Commencing 27 April: ŠKODA AUTO to resume production with protective measures

› ŠKODA AUTO to restart production at its three Czech sites on 27 April

› Protecting the workforce from the coronavirus in the best-possible way remains top priority

› More than 80 mandatory precautions to prevent staff from getting infected in the workplace

› Programme includes concrete protective measures for employees as well as organisational changes within the business

Mladá Boleslav, 24 April 2020 – ŠKODA AUTO is preparing to resume production at its Czech plants on 27 April. In order to provide the best-possible protection to prevent employees from becoming infected by the coronavirus, the car manufacturer has approved a set of comprehensive measures for all areas of the business. More than 80 individual precautions, defined together with the social partner KOVO Union, include both specific steps to keep the workforce healthy and organisational provisions to prevent the spread of COVID-19 in the workplace.

ŠKODA AUTO CEO, Bernhard Maier, said, “Production at our three Czech sites has been suspended since 18 March 2020. It was the right decision to take such drastic action in order to keep everyone safe. But now the time has come to start looking ahead with great optimism once more. ŠKODA dealerships are gradually reopening across Europe, and by successively resuming production, we are also taking the next important step in order to be able to internationally deliver vehicles to the markets again. I would like to thank all members of staff who have been working hard over the past few days and weeks to make the restart of production possible. The ŠKODA team is fully committed and eager to recommence their work.”

Michael Oeljeklaus, ŠKODA AUTO Board Member for Production and Logistics, added, “Throughout the entire shutdown, we’ve been giving preparations for the restart of production our full attention. In addition to safeguarding our supply chains, we have also looked at the opportunities for our members of staff who commute to work across borders..”

Bohdan Wojnar, ŠKODA AUTO Board Member for Human Resources, pointed out, “We have worked closely with our social partner, KOVO, over the past few weeks to develop a ‘Safe Production’ and ‘Safe Office’ concept. This will see the introduction of more than 80 concrete precautions applicable to all factory premises and office buildings in order to protect our workforce in the best-possible way once operations have resumed.”

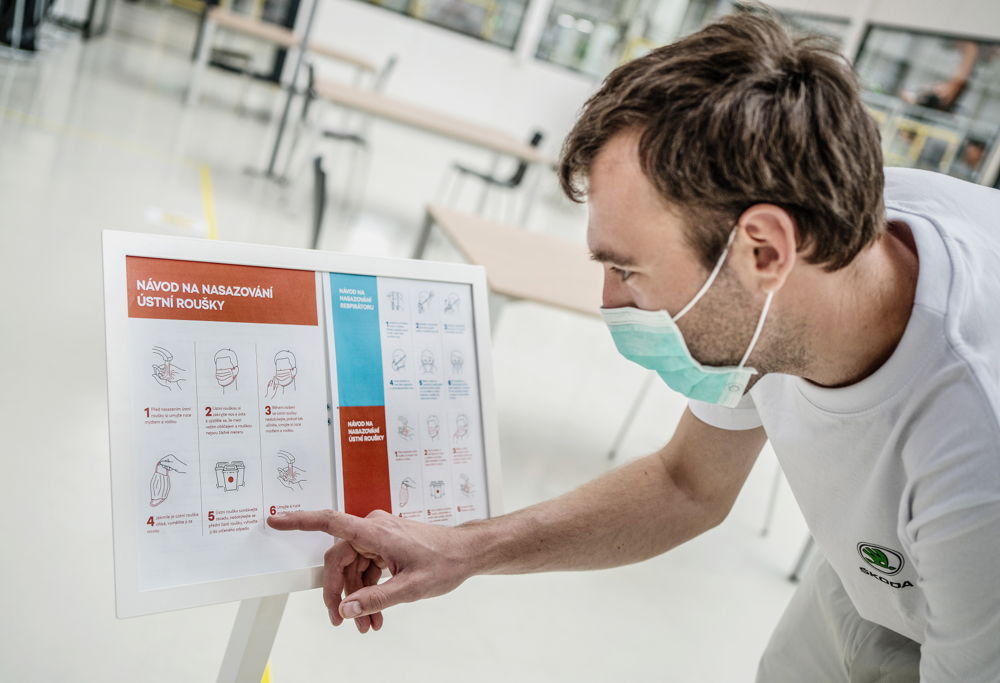

The list stipulates, for example, that all employees put on a face mask when entering the factory premises. This is also applicable to external staff. ŠKODA AUTO will provide all colleagues with the masks required, which will have to be worn at all times whilst at work. Each shift has been allocated with additional time to clean tools, telephones and keyboards as well as any materials and surfaces. Furthermore, all areas will be cleaned and disinfected even more frequently.

ŠKODA AUTO has also made some changes to daily operations in order to protect the workforce. These include adapting the way staff shuttles operate, and altering procedures at factory gates, reception points and in the canteens, as well as how working hours are recorded.

Other provisions have been made for staff in production to work in smaller, fixed teams. Briefings at shift changeover are to be as short as possible, and more breaktime areas have been made available in order to keep personal contact and the risk of infection to a minimum.

If possible, employees are encouraged to work from home, and the number of people present in the office at the same time has been reduced to ensure a safe distance can be kept from others. Again, it is important that colleagues take their breaks one after another to protect the health of the workforce in the best-possible way.

Alongside these precautions, general precautionary measures and hygiene recommendations – such as refraining from shaking hands, regularly washing or disinfecting your hands, and avoiding touching your face with your hands – are also to be followed.

The precautions to be taken after production resumes are set in three stages. Until further notice, stage 1 will see all of the measures apply in full. In stage 2, certain provisions will then be lifted. Stage 3 will allow for further, gradual easing of the measures over a prolonged period of time, ensuring this is done responsibly and in a manner that keeps people safe. At an appropriate time, the end of this third phase will enable normal daily operations to resume, meaning any currently applicable restrictions on entering the factory premises, e.g. for visitors, will be lifted.

ŠKODA AUTO is informing its workforce about the protective measures at all of its Czech sites using leaflets and posters as well as its digital channels, which feature short informative videos. Managers will also familiarise the members of their teams with the specific safety precautions that apply for their respective departments.

Together with the social partner KOVO Union

ŠKODA AUTO has defined more than 80 mandatory

precautions to prevent staff from getting infected in

the workplace.

Together with the social partner KOVO Union

ŠKODA AUTO has defined more than 80 mandatory

precautions to prevent staff from getting infected in

the workplace. The general precautionary measures and hygiene

recommendations – such as regularly washing or

disinfecting your hands – are also to be followed.

The general precautionary measures and hygiene

recommendations – such as regularly washing or

disinfecting your hands – are also to be followed.